L ᴫ 2 r y t θ 90.

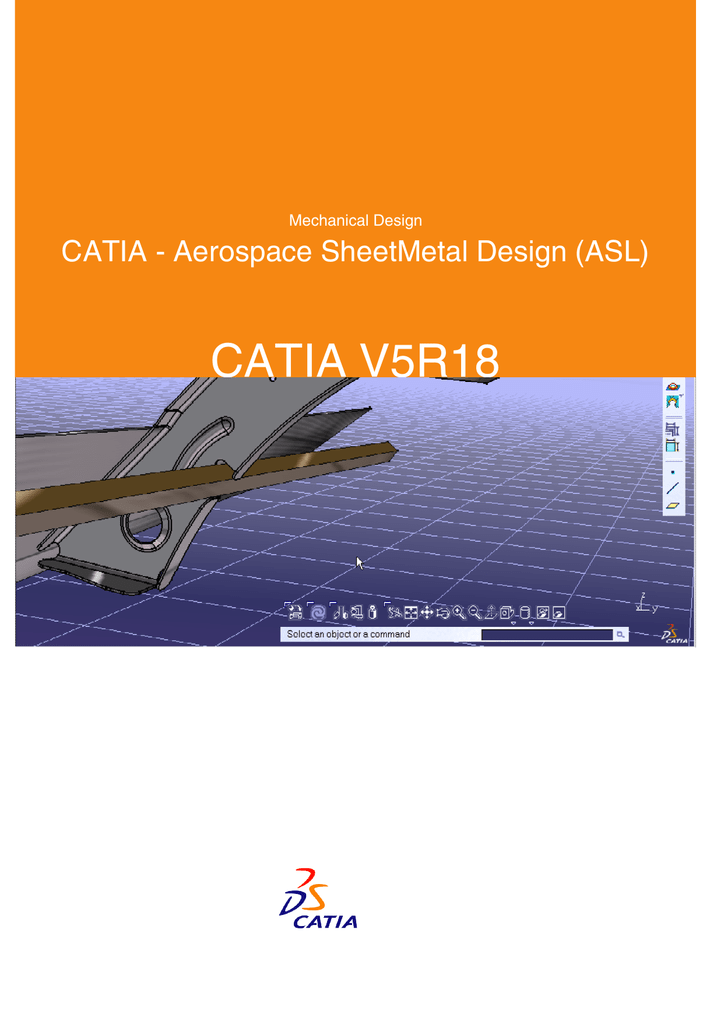

Catia aerospace sheet metal.

Although the generative sheet metal design workbench gives us the user an extensive list of tools to choose from it can have some limiting factors.

You will learn how to create and modify the design of a hydroformed sheet metal part by defining its internal features in this workbench.

Catia generative aerospace sheet metal design is a product dedicated to the definition of sheet metal parts used in the aerospace industry hydro pressed or break formed.

Catia generative aerospace sheet metal design is a product dedicated to the definition of sheet metal parts used in the aerospace industry hydro pressed or break formed.

You will also learn how to create a drawing of a flattened part.

Sheet metal depends on certain parameters 1 thickness 2 bend radius 3 bend angle.

It enables the capture of company knowledge including design and manufacturing constraints product is based on feature modeling techniques using a pre defined set of.

This page uses frames but your browser doesn t support them.

1 introduction sheet metal introduction 2 primary walls and secondary walls 3 sheetmetal parameters 4 k factor and y factor 5 various sheet metal tools 6 creating sheet metal components.

Aerospace sheet metal design in catia v5.

This page uses frames but your browser doesn t support them.

Catia generative aerospace sheetmetal design is a product dedicated to the definition of sheetmetal parts used in the aerospace industry hydro pressed or break formed.

It enables the capture of company knowledge including design and manufacturing constraints.

It enables the capture of company knowledge including design and manufacturing constraints.

For example it would generally struggle with most curvatures let alone double curvatures.

It enables the capture of company knowledge including design and manufacturing constraints product is based on feature modeling techniques using a pre defined set of.

Split viewing frameset.