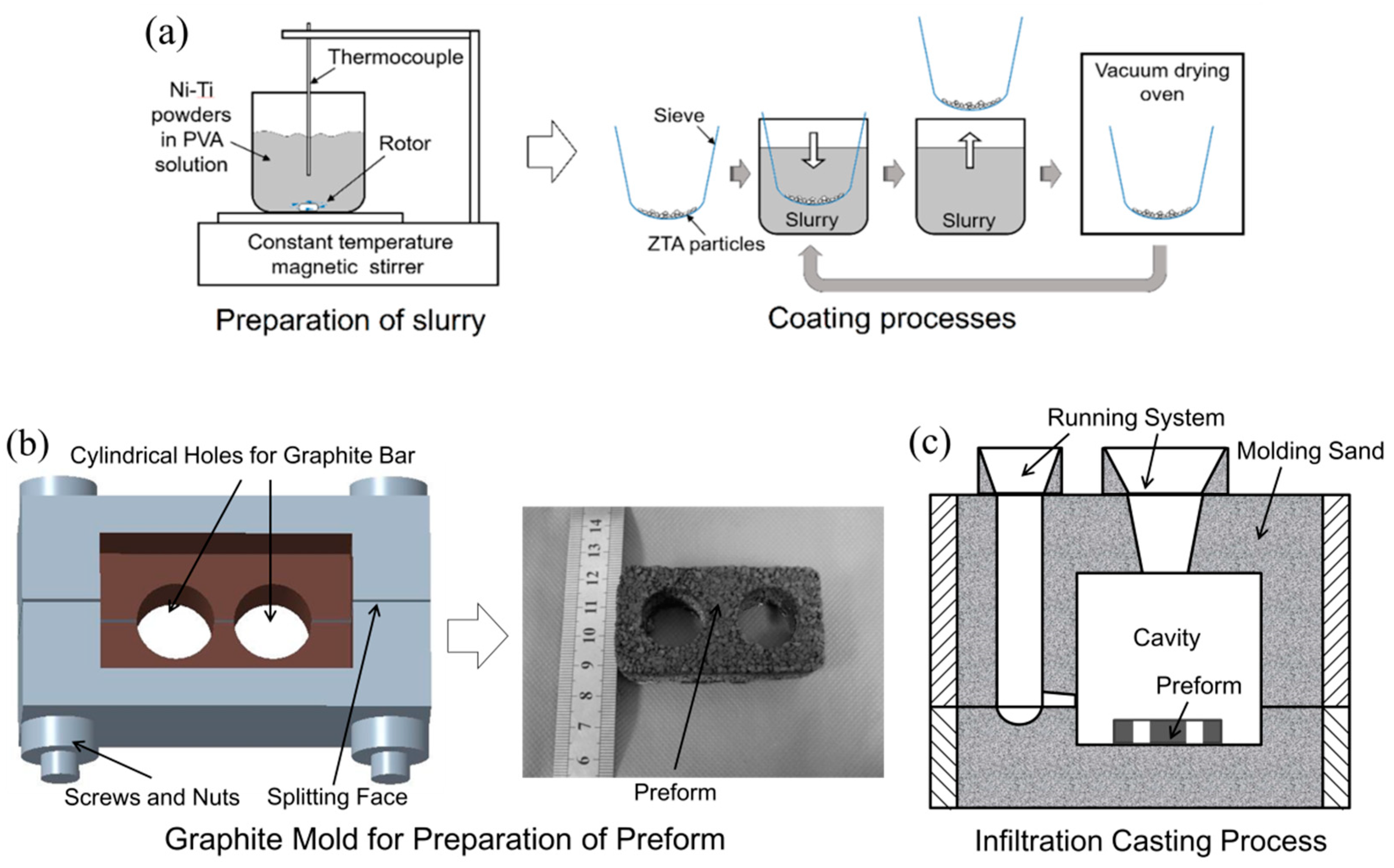

A new technique for the homogeneous infiltration of concentrated and viscous ceramic filler slurries into stacked 2d woven fabrics has been developed by introducing a flexible mold.

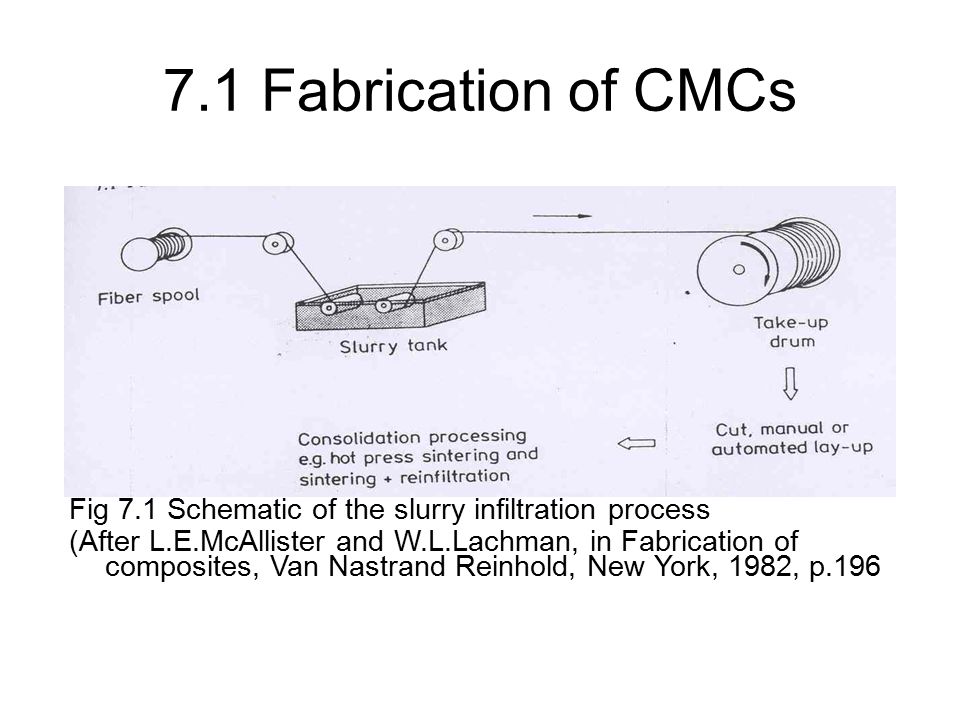

Ceramic slurry infiltration.

The slurry infiltration technique was also responsible for reducing the number of pip cycles because most of the macropores of the preform were partly filled before pip.

Simulated 2 different infiltration processes.

After the infiltration process has completed.

An efficient slurry injection combined with vibration assisted vacuum infiltration process has been developed to fabricate 3d continuous carbon fiber reinforced zrb 2 sic ceramics homogenous distribution between carbon fiber and ceramic was achieved successfully leading to an enhancement in mechanical properties.

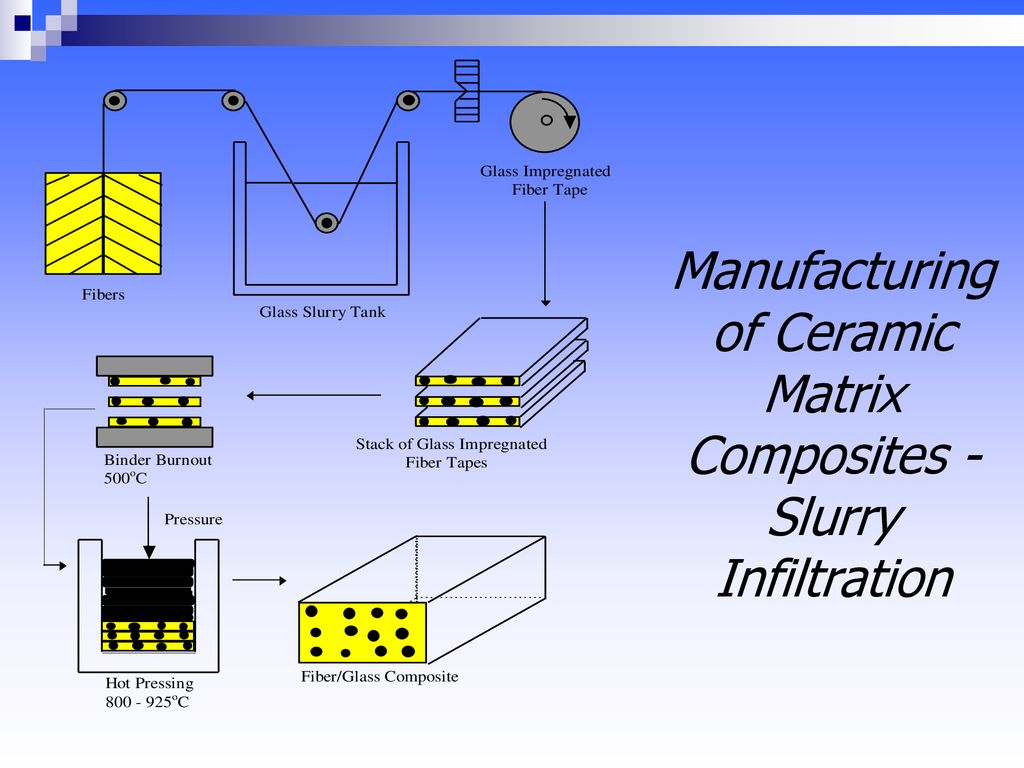

Slurry infiltration method of fabrication of ceramic matrix composites utilizes a slurry percolating into a porous reinforcing preform the infiltration process is driven by the capillary forces.

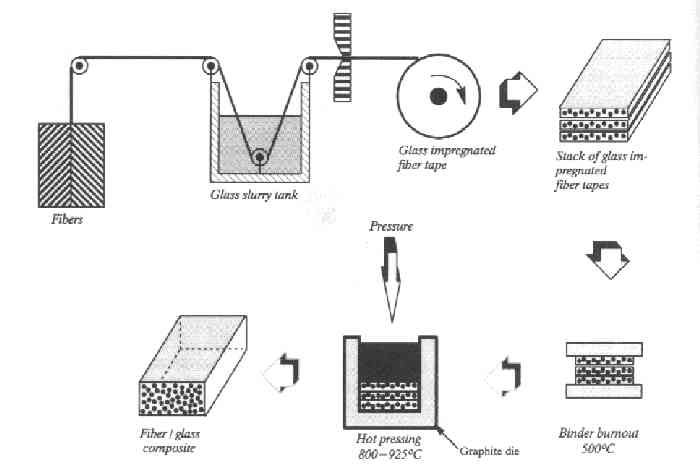

Wet lay up bath impregnation.

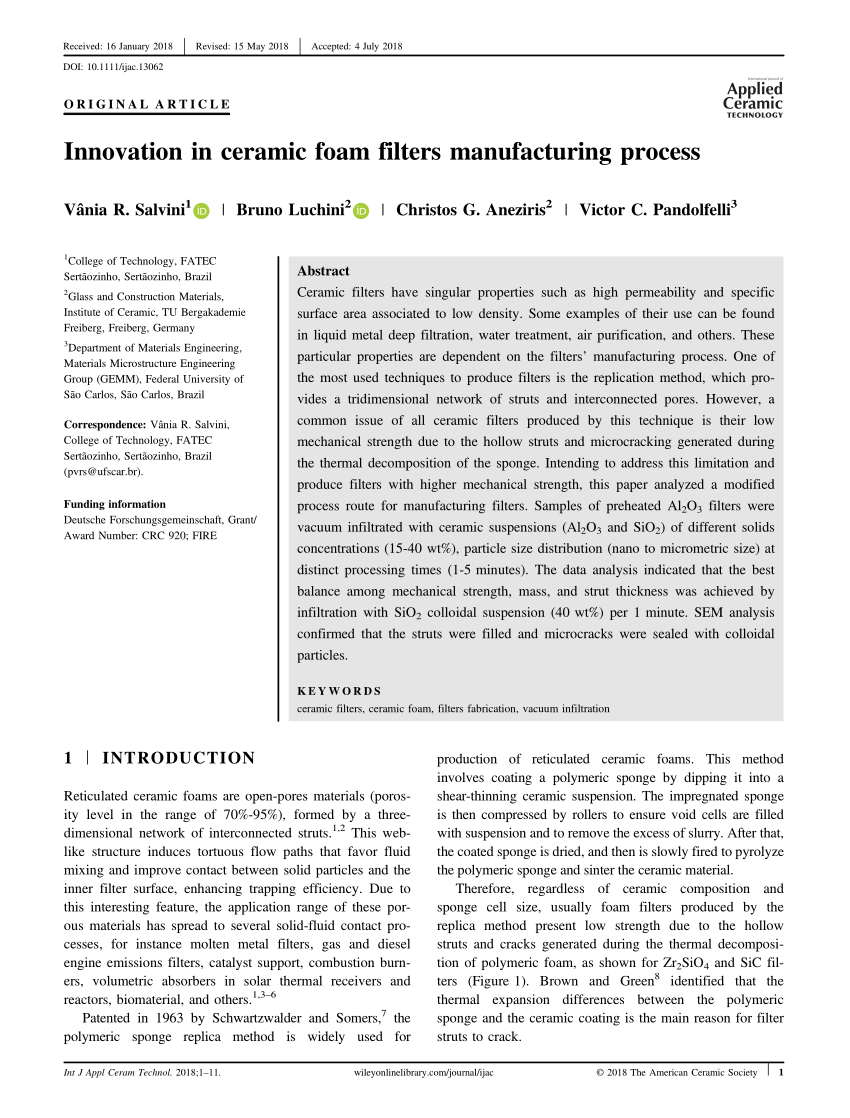

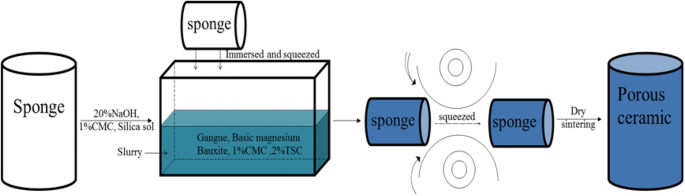

The agents will be burned out or volatilized during sintering and then many pores are left to form porous ceramic.

Combustible or volatile pore forming agents like some organics or carbon powders are added to ceramic slurry one kind of suspension.

The inner space of the mold expanded during slurry infiltration which enhanced penetration of the viscous slurry into the woven fabric layers.

For example porous mullite with air permeability can be.

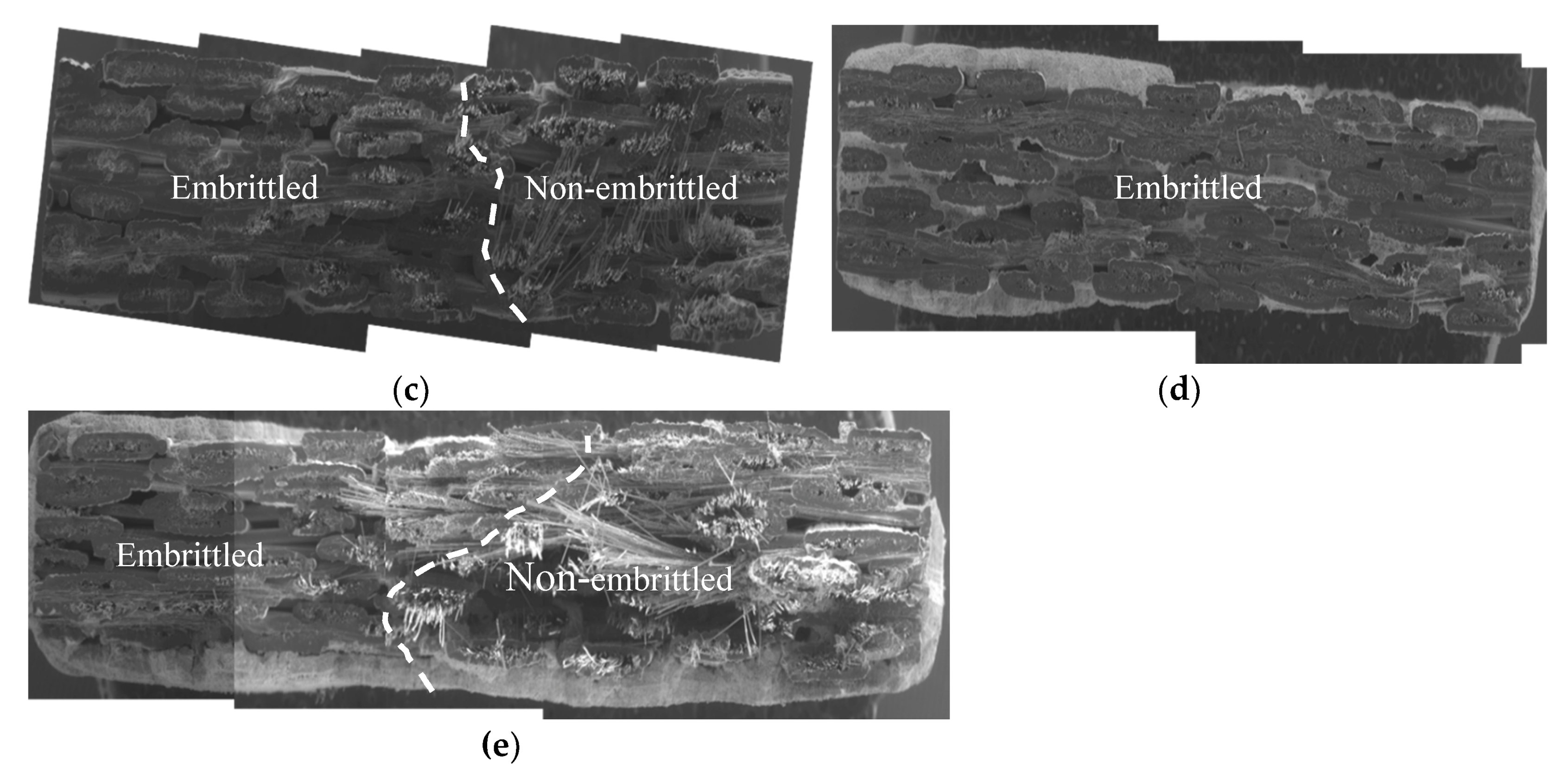

Ceramic matrix composites cmcs particularly silicon carbide fiber reinforced silicon carbide matrix sic f sic.

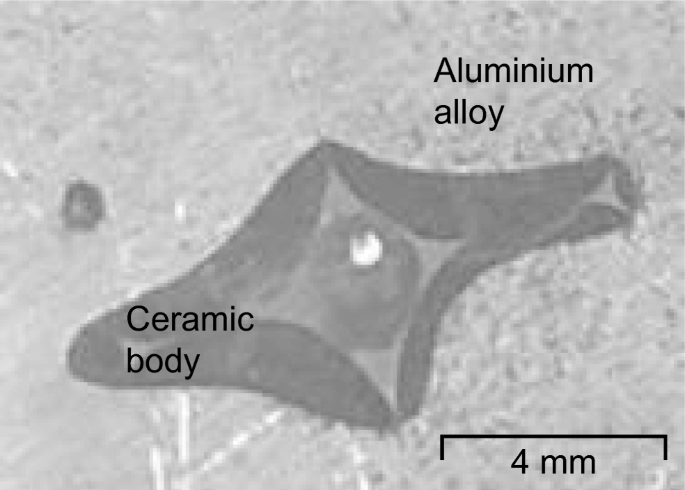

Infiltration slurry up the hollow struts generated due to burnout of the polyurethane foam template and coated the ceramic skeletons.

Thus optimization of the viscosity and thixotropy of the infiltration slurry was a key factor in preparing of the ceramic skeletons with the desired microstructure.

Sic sic matrix composite is a particular type of ceramic matrix composite cmc which have been accumulating interest mainly as high temperature materials for use in applications such as gas turbines as an alternative to metallic alloys cmcs are generally a system of materials that are made up of ceramic fibers or particles that lie in a ceramic matrix phase.

Validation with analytical results for capillary rise in a fiber.

5 2 2 slurry with pore forming agent.

Chen in porous materials 2014.

Programmed capillarity physics in existing cfd open source software.

Infiltration of molten ceramic into a fiber preform is limited by low viscosity of molten ceramics and by high temperature causing chemical interaction between the molten matrix and the dispersed phase fibers.

Infiltration of the preform with a sol preceramic precursor which undergoes polymerization gelation and is then converted into a ceramic at an elevated temperature.

Studied infiltration and subsequent fabric saturation.

Dmitri kopeliovich slurry is a dispersion of ceramic particles in a liquid carrier which may also contain additives such as binders and wetting agents.

Vacuum infiltration of concentrated sic slurry was.

This process similar to liquid state fabrication of metal matrix composites is sometimes used for fabrication glass matrix composites.