However metal s thermal characteristics may require the addition of insulation to compensate for rapid cooling during the ten minute shut down and hot restart portion.

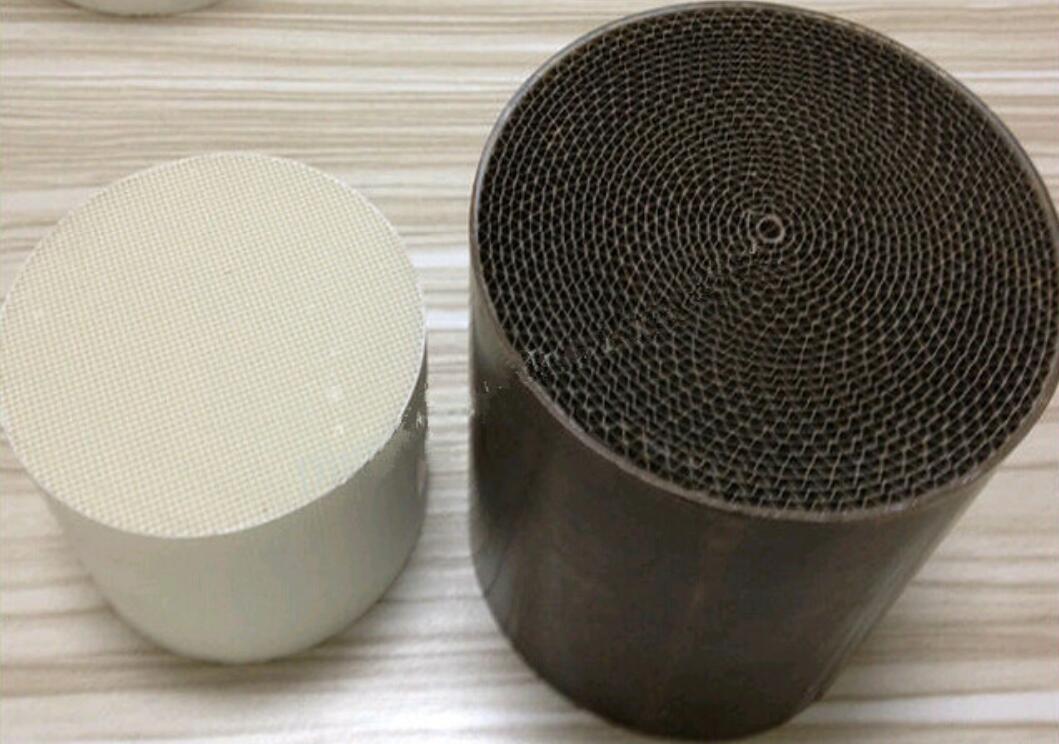

Ceramic vs metallic catalytic converter.

A catalytic converter is basically a long screen made of either ceramic or a metal foil.

The effectiveness of the converter is basically determined by the amount of precious metals present on the honeycomb substrate.

The grid also has to be heated up to ultra high temperatures to work correctly.

The catalytic converter overheats because combustion takes.

The price difference in any catalytic converter is based on the loading not the base material of the honeycomb.

Recently however many papers 1 41 have been published promoting certain advantages of metal foil substrates over conventional ceramic monolith substrates.

Many coating companies will suggest ceramic to avoid production line change overs from ceramic to metallic.

This screen is dipped and coated in a bath of liquid metal.

The recipe for this bath is made up of precious metals like platinum gold and rhodium.

Cats start working at 1200f and are most efficient around 2200 2300f.

The herringbone corrugated acr metal units outperformed equivalent plate fin metal and conventional ceramic units and approached the performance of 25 larger ceramic converters.

Ceramic catalytic converter substrate has a meltdown temp of around 1500 degrees metal substrates like those used in vibrant gesi cats have a meltdown temp of 2800 degrees.

The representative informed me that the metallic catalytic converters like part mf59956 are a bit stronger and would be good for applications where the catalytic converter is close to the header as they can handle more heat.

The metallic ones are usually used on obd1 applications.

Background ceramic pellets and more particularly ceramic monoliths have been the substrates of choice for automotive catalytic converters over the past fifteen years.

Manufacturing the most diverse metallic substrate product offering in the world.

I contacted our representative at magnaflow about the differences in the metallic and ceramic catalytic converters.

This grid is coated with a metal usually platinum or palladium that acts as the catalyst with the exhaust gases.

The precious metals used as catalysts are distributed in molecular form over a rough surfaced ceramic wash coat covering the metallic honeycomb substrate.

Catalytic converters have a ceramic grid inside that the exhaust gases flow through.

In small sizes under 6 od the ceramic is usually more cost effective per piece over the metallic but due to difficulty in packaging ceramic and extra processes required the metallic total system cost often is more advantageous.